Liquid filtration high flow pleated filter cartridges making process:

-Making cartridge pleats: Using high flow filter paper pleating machine to make filter cartridges pleats

-Welding middle seam: Using middle seam welder to do middle seam thermal welding of filter cartridges paper

-Length cutter/controller: Using high flow filter cartridge length cutter to cut/trim offer of pleated filter paper

-Cartridge shaping: Putting filter membrane with correct length into the outer cage (plastic shell) with inner core inside of the membrane to keep pleated filter cartridge have initial shape.

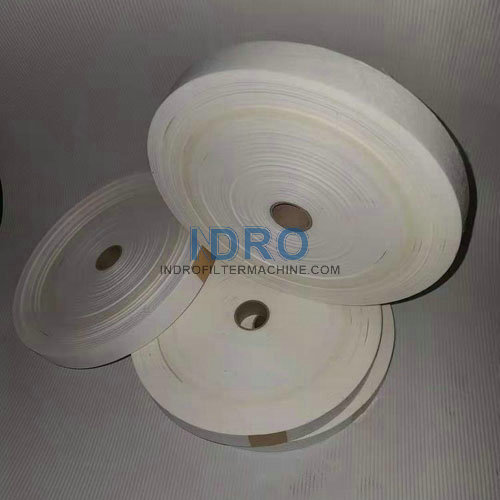

-Filter cartridge band (belt) spiral winding:wind helical wrap onto filter cartridge.

-End cap and connector ends welding: Using high flow filter cap welder to welding connector ends onto end of filter cartridges, for making 60inch, need to weld the cap on one of the ends of 20inch length or 40inch length piece. Do not need to weld cap for welding connector end.

-Length connector welding: for 20”/30”/40” long pleated filter cartridges, normally using high flow pleated filter cartridge length connecting welder to weld 2/3/4 pieces of 10” pieces together to complete 20”/30”/40”long pleated filter cartridges. For making 60inch length, after welding cap onto one of the ends of either 20inch or 40inch piece, then using length connector welder to make 60inch high flow filter.

To make one complete pieces of high flow pleated filter cartridge, you need to use following items of machines:

SIIC-M028-P1100: pleats maker, pleated cartridge filter paper pleating machine, special for folding /pleating filter paper of filter cartridge

SIIC-M028-ECW:pleated cartridge-ends cover welder, special for welding end cover of filter cartridge

SIIC-M028-LJW: high flow pleated cartridge length connecting welder, special for connecting cartridge together to become longer cartridge, such as 20", two parts, one joint, 30" three parts with 2 joints, 40" 4 parts with 3 joints, one 20 inch and one 40 inch to get 60 inch piece.

SIIC-M025-MSW: pleated cartridge-middle seam welder, special for welding middle seam of outer cover of pp pleated filter cartridge

SIIC-M028-LC: high flow pleated cartridge length cutter, special for cutting cartridge length-pleats width, do trimming of pleats edges.

SIIC-M028-BSW: filter cartridge band (belt) spiral winding machine, special for winding helical wrap onto filter cartridge, it is for making Pall wound belt filter cartridges or replacement specially.