PVDF/ PFA/PTFE/ECTFE/PP Plastic Pipe Tube Welder For High-Purity Fluid Systems

Model No.: SIIC-M041-PTW

Indroductions To Function and Principle:

INDRO Plastic pipe welders for high-purity systems primarily utilizes fusion welding methods, such as infrared (IR) fusion and butt fusion, which create seamless, leak-proof joints critical for preventing contamination in demanding applications like semiconductor and pharmaceutical manufacturing.

For high-purity systems, top choices are thermoplastics like PVDF, PFA, PTFE, ECTFE and Polypropylene (PP) due to their low extractables, chemical resistance, and smooth surfaces, essential for semiconductors, pharma, and ultrapure water (UPW).

SIIC-M041-PTW is specialized welder equipment designed to heat PVDF, PFA, PTFE, ECTFE and Polypropylene (PP) tubes,tubes ends and or fittings to a controlled temperature to creat a strong, chemically resistant, seamless joint suitable for high-purity fluid handling systems like chemical processing, pharmaceutical and semiconductor pipelines.

Technical data:

Machine Material:SS304

Ends cross-section flatten: automated planing depth, trimming off to make section smooth before welding.

Welding System: Infrared Welding/Hot Plate Welding

Clamp Sets: to be custom made and included in the machines.

Control mode: With PLC

HMI language: English/Chinese

Power supply:5KW, 220V/50HZ/Single Phase, or 380V/50HZ/3 Phase, to be custom made as per customer's requirement

Available tube/fitting ends size: custom made as per customer's requirement

Available tube/fitting ends materials:PVDF, PP, PPn, ECTFE and PFA

Machine dimension:80x70x90cm, or others to be different depends on customer's requirement.

Features:

/Movements which affect the welding performance are controlled by machine

/Stable, precise, homogeneous and clean welding/bond

Applications:

/Used for chemical processing, semiconductor manufacturing, pharmaceuticals, and high-purity filtration systems where long service life and reliability are critical.

/Used for handling aggressive chemicals such as chlorine, hydrochloric acid, sulfuric acid, and mixed solvent systems.

/Used for ultrapure water (UPW), biotech, food-grade processes, and filter cartridge manufacturing or testing applications.

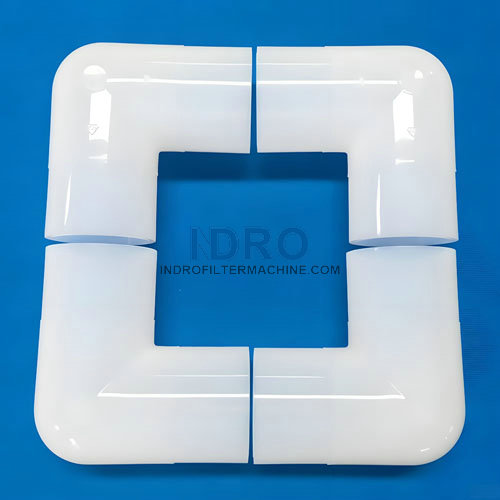

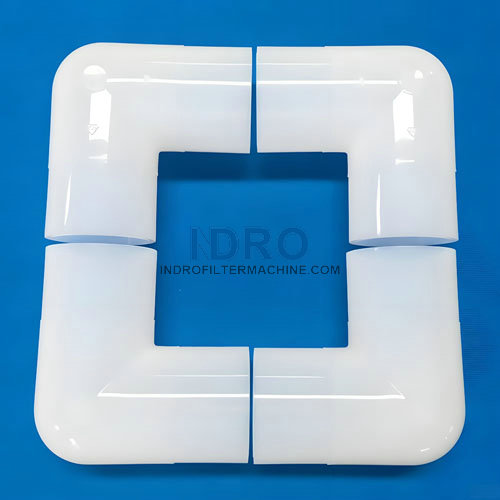

Photos examples of PVDF/ PFA/PTFE/ECTFE/PP Plastic Pipe Tube: