automatic filter paper pleating machine-W-M pleats maker

Item No.: SIIC-M035

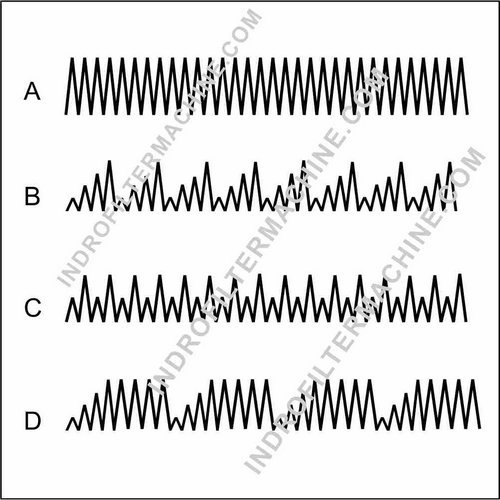

SIIC-M035 is automatic pleats making line, special for making pleats of liquid filtration pleated filter cartridges, air filters and dust pleated cartridges, suitable for common type, W-type, M-type, step-height type and multi-layer filter paper pleating.

INQUIRY