Dust collector filter bag making machines production line

Applications:

Specially used for making dust collector filter bags and filter sleeve, filter tube.

Both woven fiberglass and needle punched felt filter material are available.

Specification:

The complete production line include filter bag body sewing part, filter bag top/bottom sewing machine, snap band sewing machine, strips cutting machine, snap band punching and cutting machine, disc bottom machine, supporting ring sewing machine, bag body welding machine and filter roll cutting machines.

1. Filter bag body sewing machines

Special for stitching needle punched felt or woven cloth dust collector filter bag body.

Available models options:

Model No.: SIIC-M001 automatic filter bag sewing machine-stitching filter bag body and cutting bag length automatically

Model No.: SIIC-M005 semi-automatic filter bag sewing machine-stitching filter bag body automatically

Model No.: SIIC-M007 manual filter bag body stitching machine-stitching filter bag body manually

The main features of different models

| Model No. |

Features |

| SIIC-M001 |

Sewing filter bag body automatically and cutting bag length automatically, 7-12 meters per minute

|

| SIIC-M005 |

Sewing filter bag body automatically, without cutting bag length function, 7-12 meters per minute |

| SIIC-M007 |

Sewing filter bag body manually |

2. Filter bag top/bottom sewing machine

2. Filter bag top/bottom sewing machine

Special industrial double need short arm stitching machine for sewing filter bag top and bottom.

Available model No.: SIIC-M010

3. Filter bag snap band sewing machine

Special industrial flat sewing machine for sewing snap band strips which are covered onto the carbon steel or stainless steel snap band.

Available model No.: SIIC-M014

Accessories: snap band folder, special folder to folding the snap band strips.

4. Filter bag snap band strip cutting machine

Special cutting machine for cutting snap band strips which are made of filter cloth.

Available model No.: SIIC-M015

5. Filter bag snap band punching/making machine

Special machine for punching and cutting carbon steel and stainless steel snap band which are used for filter bag top.

Available model No.: SIIC-M016

6. Filter bag disc bottom making machine

Special machine for cutting disc bottom which are used as filter bag bottom.

Available model NO.: SIIC-M017

7. Filter bag support ring sewing machine

7. Filter bag support ring sewing machine

Special industrial long arm stitching machine for sewing the supporting rings at the middle of filter bag body.

Available model No.: SIIC-M011

8. Filter bag body welding machine head

Special hot air welding machine for welding felt filter bag body

Be to replace the sewing machine part in the automatic filter bag sewing machine line.

Available mode No.: SIIC-M009

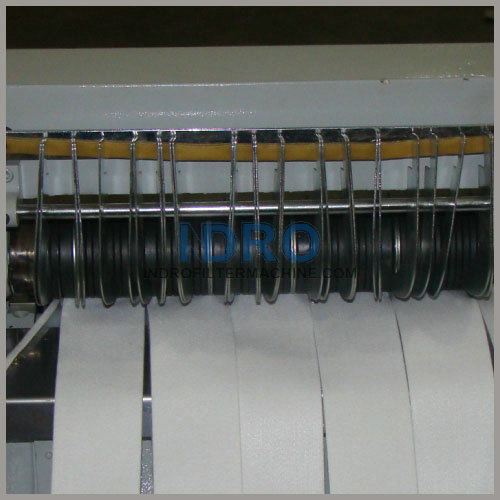

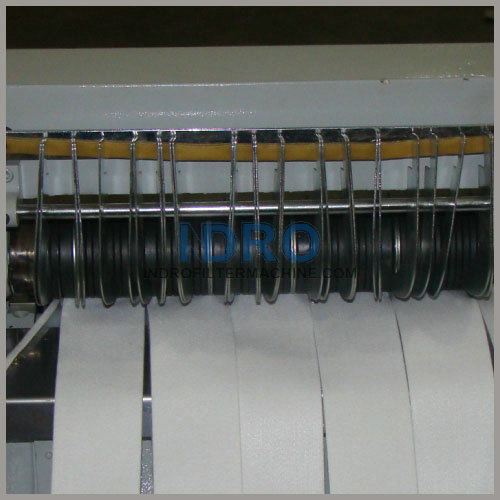

9. Filter cloth cutting/slitting machine

Machines for cutting filter rolls width into different small widths according to exactly filter bag diameters.

Available modes:

Model No.: SIIC-M019 cutting filter rolls width automatically.

Model No.: SIIC-M020 cutting filter rolls width manually.

Main features of different models:

| Model No. |

Features |

| SIIC-M019 |

Cutting filter rolls width automatically |

| SIIC-M020 |

Cutting filter rolls width manually |

How to select machines for making dust collector filter bags?

First, confirm the filter bag material. Your filter bags are made of felt or woven fiberglass?

How to select machines for making dust collector filter bags?

First, confirm the filter bag material. Your filter bags are made of felt or woven fiberglass?

Secondly, confirm the filter bag sizes, including diameters and length.

Thirdly, confirm the filter bags shapes, bag top/bottom types.

The bags are with standard shape of tube shape?

Bag tops are standard snap band top?

Bottoms are disc bottom?

Fourthly, select the necessary machines according to the budget, working spaces and production capacity requirement.

Download one guide which helps you how to select machines:

/u_file/2012/file/00e49a366d.pdf